Pearl Acoustics are manufacturers of high quality, bespoke HiFi equipment.

Purity, simplicity and sustainability are our three defining words.

Pearl Acoustics is a privately owned HiFi equipment and loudspeaker manufacturer, specialized in designing extremely high quality products for the high end, domestic Hi-Fi market. It was the brainchild of Harley Lovegrove a business man and entrepreneur who was totally passionate about music and HiFi and who had been designing loudspeaker enclosures since the age of nine. Brought up in south east England (some say the centre of the world’s loudspeaker design in the 1960’s with both KEF and Lowther being in the vicinity) Harley’s passion for HiFi & loudspeaker building was cemented by regular visits to the famous ‘Lowther’ loudspeaker company factory which was conveniently located on the way home from his primary school in Bromley.

Today, Pearl Acoustics is headed up by his daughter Summer Lovegrove as CEO.

Ajay Verma is our Customer & Technical Services Director and Dries Ceuleers our Production Director. Together, they head up our international sales, manufacturing and logistics team.

Harley Lovegrove has retired from the day to day running of the business but remains a member of the board of directors of Pearl Acoustics Ltd, focusing his time increasing awareness of the brand via our YouTube channel, and his sound recording and music charity activities.

The arrival of a brand new vacuum tube, power amplifier, brings Pearl Acoustics into a new era. The 170 amplifier is a totally new, bottom up design based upon grounded knowledge from the past. By bringing together a an extremely eclectic design team, we were able to look at our design without falling back on pre-conceived design ideas and techniques.

“For me speaker building is more like instrument making. It’s a passion and a craft all at once. Sure there is science too but not many Luthiers know much about science, they don’t need to test their cellos, violins or classical guitars in anechoic chambers to know if they are any good or not. All I have done over these last five decades is to try to design and build the best possible enclosures and then to find really great drivers (ones that can cover the widest possible frequency range effortlessly). By teaming up with Mark Fenlon of Mark Audio, I now have my own custom drive units made exclusively for the Sibelius SG and CG models.”

-Harley Lovegrove

In February 2024,after several years of development behind the scenes, Pearl Acoustics introduced their first power amplifier. A vacuum tube, single-ended design. Completely designed and built in the UK, the Pearl Acoustics 170 is intended not just for the Sibelius loudspeaker but to every make and model.

The 170 Single-Ended Vacuum Tube Power Amplifier

Our 170 stereo power amplifier has been designed to deliver a refined, organic and natural soundstage, without being over analytical. With the 170 we wanted realism, with a sense of ‘being there’.

The Pearl Acoustics 170 single ended power amplifier, is a totally new ground-up bespoke design, the result of working together with some of the best minds in the business. The amplifier features an extremely short signal path, bespoke, custom designed output transformers and power supply circuitry.

Our design concept has been focused on sustainability by incorporating product longevity into every aspect of its design, without limiting its clean, engaging and holographic sound performance. Musical finesse with very fine details and superb dynamics have been combined into a piece of equipment that is designed to last ‘forever’.

About the Sibelius loudspeaker:

The world renowned speaker designer and builder John Bowers of Bowers & Wilkins famously once said

“The very best speaker design only needs one drive unit but if you cannot build it with one then use two. If you cannot build it with two then use three. If you need more than three then change your design.”

Sadly John Bowers is not around anymore to hear what our team has built, but if he were, I think he would be pleased with what we have achieved.

The Sibelius loudspeaker is named after the great Finish composer Jean Sibelius (1865-1957).

Throughout the composer’s career his only passion was to create fine works that brought to life the rich pallet of sounds and colour that reflected the purity of nature that surrounded his home in Järvenpää. From the bright metallic crispness of the brass and woodwind section of the orchestra to the thunderous sound of kettledrums and double basses and the delicate whispers of the strings. Sibelius’ music could switch from full on to the most delicate nuances of a solo violin, oboe or flute in fractions of a second. But most of all, Sibelius created exceptional sound imagery, the breadth and depth of his music ensuring its rightful place in the repertoire of concert play lists.

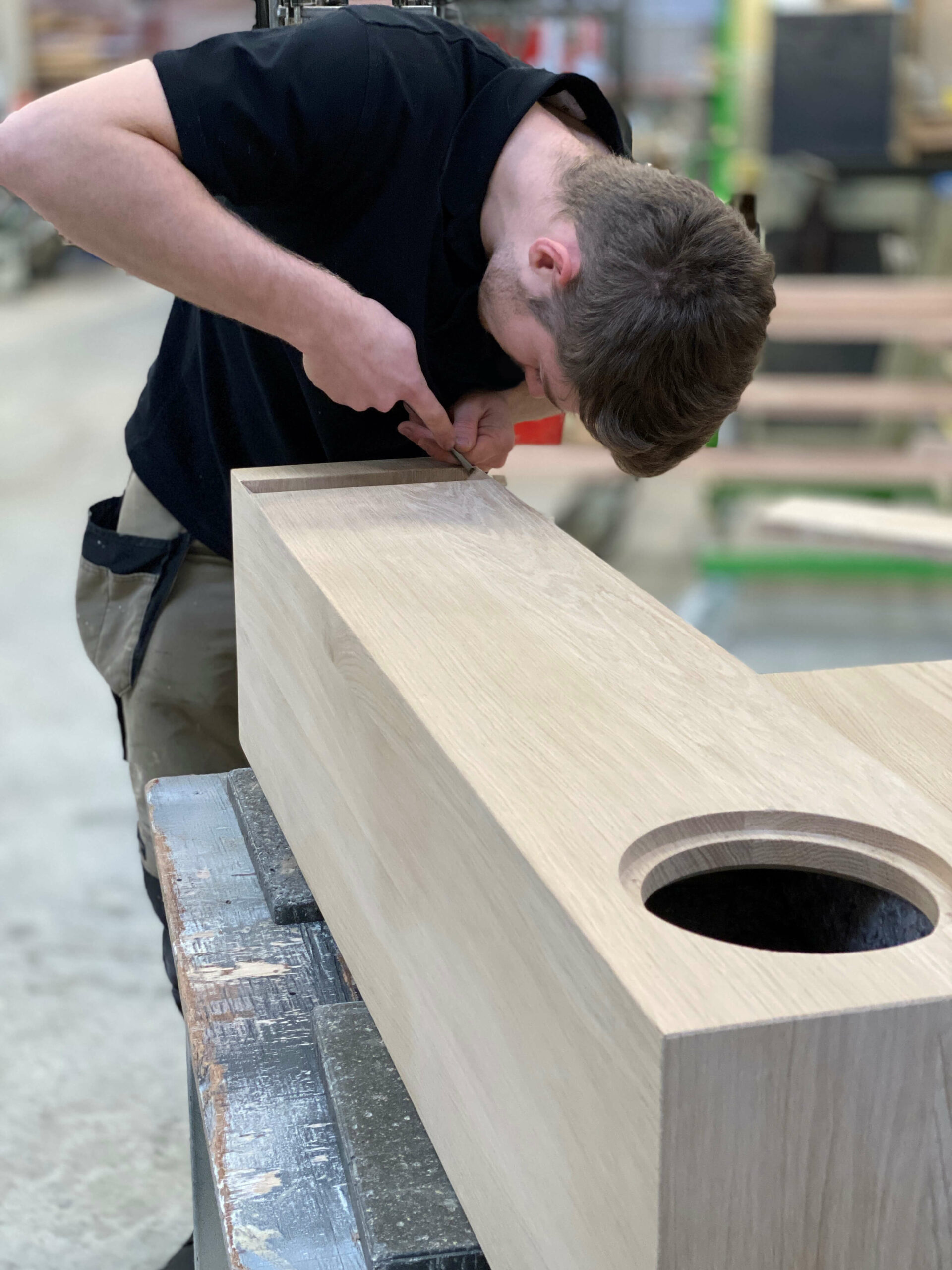

Making a pair of Sibelius enclosures is mostly handwork. The whole process takes approximately 12 weeks from the French oak entering the joinery, to the finished pairs leaving for a customer.

Selecting the French Oak, right through to gluing, clamping, chiseling and preparing for finishing.

Before we can apply a stain and a topcoat, be it a varnish or natural wax-oil, the enclosure must be as good as we can make it. Any oversights here means triple work later on!

Hand sanding, smoothing with a steel blade and routing the edges, are all part of the pre-finishing process.

Every enclosure is unique. They need to be selected for their individual characteristics and their suitability for the colour and type of finish our customer is looking for.

Applying a dark stain is a skilled job. It takes a steady hand, time and patience.

From the ‘90’s to the present day…

In the early 90’s Harley made a major breakthrough in enclosure design. It was a complete reversal on his previous designs – moving away from highly complex crossovers and electronic filters. His new design was based upon the principles of the legendary work of Paul Voight in 1939.

Paul Voight –

Courtesy of the Lowther Museum

The result was a quarter wave, front loaded horn with a full range driver plus tweeter for the last three octaves. It utilized a very unfashionable (at the time) simple, two component 6db per octave crossover. Harley’s new minimalist approach to design was bringing him closer to his goal but he knew that it would be even better if it could be driven by a single drive unit. Unfortunately there was nothing of sufficient quality that could truly handle the upper and lower octaves. Not even Fostex or Lowther could produce something that would comfortably go up to and beyond 18KHz, and certainly not with the amount of power needed to reproduce the full range of an orchestra at realistic sound levels.

In 2012 two important things happened: Firstly; Harley discovered the drive units manufactured by Mark Audio, especially the Alpair 7 and Alpair 10. These drive units were what he had been waiting for all these years; Purity, power handling and incredible sound stage dynamics. Secondly Harley met Chris Cabergs the owner of a bespoke joinery business in Diest, Belgium. Chris was specialized in working with high quality natural timber, especially Oak and Beech.

Chris, like Harley was a perfectionist. He understood cabinet construction and could take Harley’s designs and give them the rigidity that he was looking for, without the need for internal edge bracing (which causes too many acoustical problems). Chris, an engineer from training was also interested in Hi-Fi and acoustics and after successfully building Harley a pair of Scott Lindgren’s Frugel-Horn Mk3’s utilizing the Alpair 7’s, he set about building Harley’s classic enclosure design out of three centimetre thick, slow grown, slow aged French Oak. After several false starts and much perseverance, Chris delivered the result Harley was looking for, and Harley now had what he always wanted: a loudspeaker enclosure that could accurately reproduce the dynamics and frequency range of a symphony orchestra. After three more years of testing, improving and working closely with Mark Fenlon’s team in Hong Kong, The Sibelius SG and CG finally came off the production line, powered by a fully customized Mark Audio drive unit, exactly to the Sibelius’ design needs.

After several months of additional fine tuning and experimenting with a wide range of acoustic damping materials, the first commercial production specification Sibelius (the name of the composer that Harley dedicated his design to) was produced and introduced to a waiting public.

The rest they say is history…